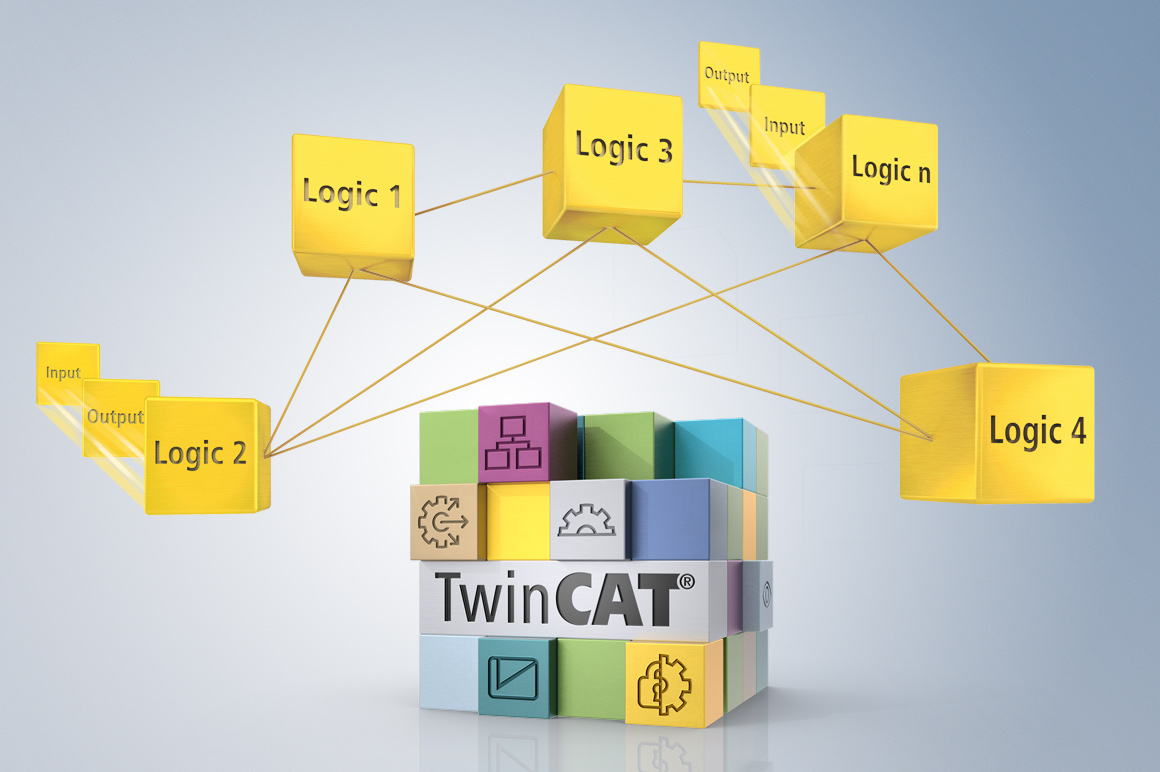

The open, PC-based control technology as well as specific technology function blocks from the TwinCAT Hydraulic Library offer an optimal platform for automating a wide range of folding and bending processes efficiently and in a time-saving manner. The various function blocks can be used completely or individually. For folding, for example, ready-made technology function blocks are available for the press beam and the back gauges. In addition, it is possible to use algorithms for the calculation of the insertion depth as well as for the positioning of the back gauges. The automatic calculation of the bending order avoids collisions during the folding process. The software is designed with open interfaces so that users can easily implement individual adaptations and extensions and add their own algorithms. Moreover, machine manufacturers have access to the whole Beckhoff I/O range for integrating additional functions such as safety technology, acquisition of energy data, condition monitoring or optional peripheries.

Beckhoff technologies and components optimize the bending process

Round bending machines with three or four rollers are ideal candidates for automation with Beckhoff components. During pipe production, the rollers constantly have to follow new setpoints. Using high-resolution CAM tables in conjunction with external setpoint generator, any tube geometries can be produced using the Motion Control solution from Beckhoff. In addition, there is the option to obtain setpoints from a higher-level NC I. Regardless of whether you are dealing with small electric or hybrid machines or large, fully hydraulically driven machines with a sheet width of 24 m and a sheet thickness of more than 300 mm, PC-based control from Beckhoff offers a comprehensive, well-coordinated and scalable component portfolio:

- A large selection of standard operating devices for round bending machines enables ergonomic operation.

- In conjunction with EtherCAT, the IP20 terminals enable space-saving, central installation in the control cabinet.

- The TwinCAT software function blocks for Motion Control and the Beckhoff servo drives and motors provide a universal Motion Control architecture for electric and hydraulic axes.

- Tailor-made cam plate modules support precise pipe production.

- condition monitoring terminals for controlling hydraulic pressures, pump vibrations and supply networks

Bending machines are indispensable for pipe and profile processing. The high positioning accuracy required for pipe bending places particularly high demands on the control technology. Thanks to position controller cycle times of 31.25 µs, as offered by the Beckhoff servo drives, these positioning requirements can easily be met. In addition, Beckhoff is the ideal partner for the automation of auxiliary units such as pipe feeders.

- Motors with OCT (One Cable Technology) reduce the cabling effort by 50 %.

- The AX8000 multi-axis servo system optimally supports the bending process thanks to its high control accuracy.

- IP20 terminals in conjunction with EtherCAT enable space-saving, centralized installation and reduce the cabling work.

- The TwinCAT software function blocks for Motion Control and the Beckhoff servo drives and motors provide a universal Motion Control architecture for electric and hydraulic axes.

- TwinCAT CNC comprises ready-to-use processing solutions based on DIN 66025/ISO.

In the folding process, it is essential to balance mechanically coupled axes with micron accuracy. These requirements can easily be met using the ready-made gantry or master/slave axis coupling blocks from Beckhoff. The non-linear gear units normally used here can be represented by closed equations or in the form of lookup tables.

A comprehensive portfolio of software- and hardware-based control components is available for swivel bending machines with hydraulic or electric drive technology of any size:

- EtherCAT as a fast Ethernet-based fieldbus for I/Os and drive technology

- Motors with OCT (One Cable Technology) reduce the cabling effort by 50 %.

- The IP 67 EtherCAT Box modules enable decentralized process data acquisition directly at the machine.

- The ultra-compact Industrial PCs from the C60xx series save installation space in the control cabinet.

- TwinCAT PTP and TwinCAT Hydraulics from Beckhoff provide a universal Motion Control architecture for electric and hydraulic axes.

- By supporting standardized protocols such as MQTT and AMQP, relevant process data can be transferred to a cloud service.

In die bending, an upper die pushes the sheet into a V-shaped lower die. Particularly with free bending, very precise position guidance is essential for a perfect bending result. In addition, the back gauges ensure the appropriate leg lengths. Beckhoff offers tailor-made solutions for all bending process requirements:

- With the aid of compact drive technology from Beckhoff, the back gauges can be addressed directly in the terminal network. This enables significant savings in terms of space requirements and wiring effort.

- TwinSAFE, the electronic safety technology from Beckhoff, offers solutions for safe working at the press brake.

- TwinCAT PTP, TwinCAT Hydraulics and the Beckhoff servo drives and servomotors provide a universal motion control architecture for electric and hydraulic axes.

- Characteristic diagram linearization enables micrometer-precise positioning of the upper die.

- Consistent implementation of all functionalities as software modules avoids the need for special external hardware. This reduces hardware costs, engineering effort and lifecycle costs.

- TwinCAT HMI provides an ergonomic user interface in HTML5 with optional integration of bending algorithms.

Application reports and brochures

- 20.03.2025 | Application report

Closed profile rings – the advantage of the fourth bending roller

Moser-Baer AG, SwitzerlandMoser-Baer AG in Switzerland is streamlining the production process for its world-famous railroad clocks with a new type of profile bending machine: With four bending rollers instead of the usual three, the Mobamatic MPB23 profile bending machine, with the mechanical platform developed and built by Moser-Baer, can bend a wide variety of profiles without straight end pieces. The automation specialist Pneutronic AG implemented the complete drive and control technology. PC-based control and the AX8000 multi-axis servo system with TwinSAFE ensure a compact design, precision, and safe operation without safety guards and laser scanners.

- 02.09.2024 | Application report

Scalable for the future with fully integrated, open control technology

Cincinnati Incorporated, United StatesCincinnati Incorporated (CI) has been building sheet metal processing equipment for 125 years and continues to support its durable machines for decades. The company is able to do this because it develops everything in-house, from the hardware to the software. However, the further development of proprietary control technology became too costly and challenging to support. Since the switch to PC-based control, the only limits to development have been physical, according to the engineers at CI.

- 06.11.2023 | Application report

High die casting quality through optimum control of vacuum generation

AJYa Vacuum Technology, ChinaIn die casting, vacuum generation in the shot chamber and mold cavity helps to avoid air and gas inclusions in the castings, as these would impair the stability of the finished parts. For this purpose, AJYa Vacuum Technology from China developed a complex but particularly effective multi-stage solution. A suitable control platform was implemented in cooperation with the automation partner Beckhoff.

- 11.10.2022 | Brochure

High performance built in: PC-based control for sheet metal working

As a specialist in PC-based control technology, Beckhoff provides proven, high-performance automation solutions for sheet metal working.

- 15.09.2021 | Application report

PC control guides precise shaping of the heaviest steel plates

Haeusler, SwitzerlandHaeusler AG, based in Duggingen, Switzerland, is a leading specialist in large-scale facilities for forming metal plates. At the end of 2020, a giant 1,245-ton straightening machine was delivered to one of the largest shipyards in China. The company explains that this plant, the largest of its kind in the world, is used in the production of oil tanker hulls. In this context, PC-based control technology from Beckhoff ensures that the enormous forces for precisely forming steel parts are guided in the right direction.