Beckhoff’s extensive range of technologies and solutions underscores its position as a highly experienced partner and solution provider for a wide variety of machine tool categories and performance classes. It’s been that way ever since the company was founded in 1980. In addition to solutions for milling, turning, and drilling machines, countless customers worldwide are leveraging PC-based control to develop and implement their innovative machining processes and ensure they maintain their technological edge. This includes applications such as laser cladding, laser cutting systems, EDM machines, and additive manufacturing.

Current applications

High-tech laser cutting system relies on powerful IPC platform and EtherCAT: Maximum precision and speed in laser cutting applications

The outstanding beam quality of the fiber laser has positioned it as the technology of choice for fine sheet metal cutting as it allows for precise cuts and very narrow kerf widths while maintaining high contour speeds. In order to guarantee these parameters, Polish manufacturer Power-Tech relies on the use of fiber lasers and powerful automation technology from Beckhoff in its Eagle brand laser cutting machines.

Laser cladding with TwinCAT CNC: High speed and precision perfectly aligned in a software-controlled solution

In contemporary applications, laser cladding is often used for coating rotationally symmetrical components. Ponticon GmbH, based in Wiesbaden, Germany, is expanding its range of applications to include coating and additive manufacturing of any geometries with the pE3D system. The requirements regarding the precise control and coordination of the tripod, rotary/swivel table, and laser would have been difficult to implement without TwinCAT CNC, EtherCAT, and eXtreme Fast Control Technology (XFC) from Beckhoff.

Open PC-based control and drive technology in additive manufacturing processes: For high-precision, high-speed 3D printing with aluminum alloys

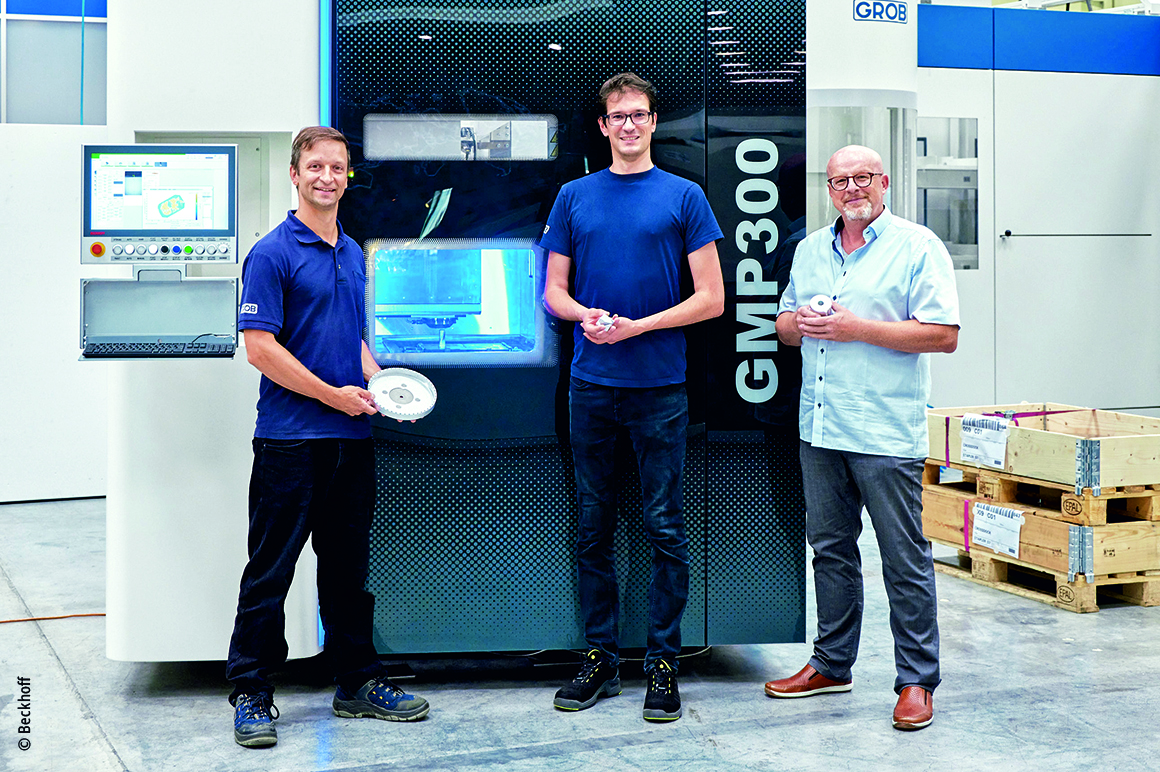

As a globally operating family business, GROB-Werke has been developing systems and machine tools for customers including the most renowned automotive manufacturers for over 95 years. This period has been characterized not only by technical innovations, but also by the opening up of new markets. A prime example is the field of additive manufacturing, for which the first prototype machines were developed in 2019. With the new GMP300 Liquid Metal Printing machine, which is automated with PC-based control, wires made of aluminum alloys can now be used cost-effectively and efficiently in the printing process to achieve precise and fast 3D printing.

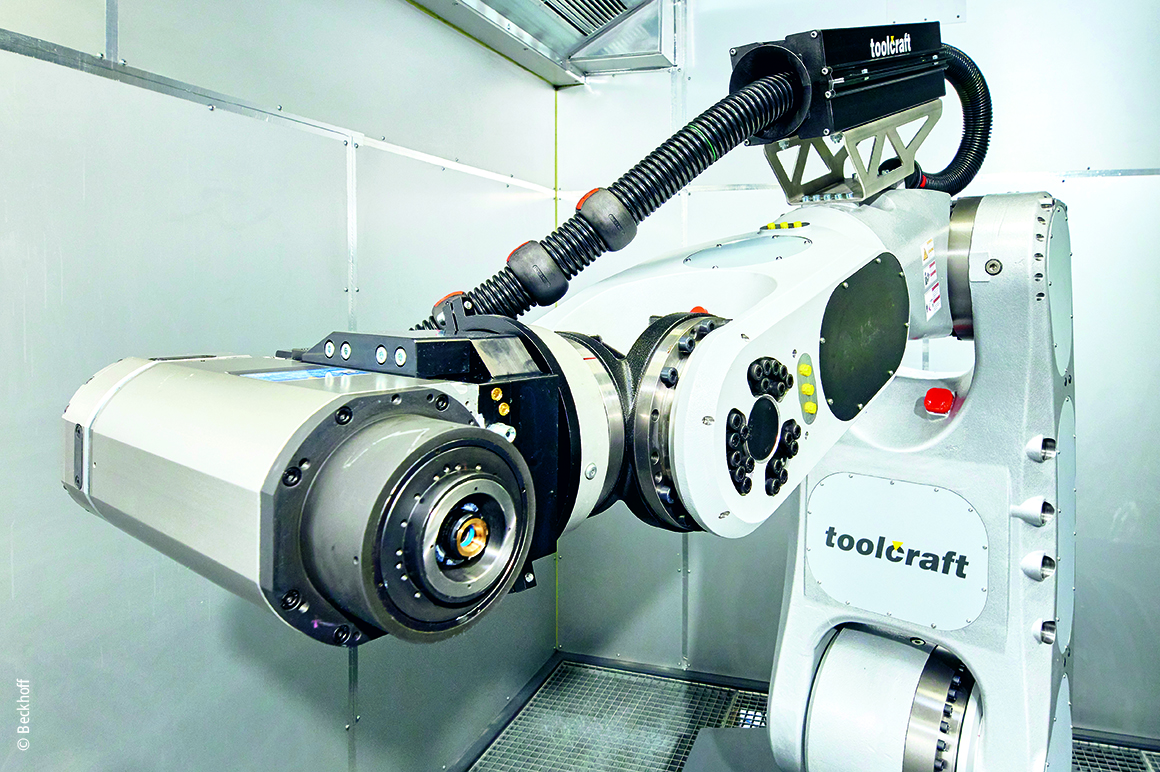

TwinCAT CNC and drive technology in machining applications: High-precision part machining with CNC robots

Anyone who believes that jointed-arm robots lack the precision required to machine hard materials has clearly not yet come across toolcraft. Daniel Distler and Andreas Bauer use TwinCAT CNC and PC-based control from Beckhoff to implement robot cells for precise machining of components – including solid blocks of silicon carbide and gray cast iron.

Application reports

- 02.09.2024 | Application report

Precise gear machining every second

Tec for Gears, GermanyMany innovations have their roots in the Black Forest, including radial chamfering, which Tec for Gears (TfG) from Furtwangen are using to automate a previously predominantly manual production step with TwinCAT PLC/NC PTP and EtherCAT oversampling terminals from Beckhoff, among other things. The gear chamfering and deburring process becomes precise, reliable, and so fast that it can be integrated directly into production.

- 02.09.2024 | Application report

Scalable for the future with fully integrated, open control technology

Cincinnati Incorporated, United StatesCincinnati Incorporated (CI) has been building sheet metal processing equipment for 125 years and continues to support its durable machines for decades. The company is able to do this because it develops everything in-house, from the hardware to the software. However, the further development of proprietary control technology became too costly and challenging to support. Since the switch to PC-based control, the only limits to development have been physical, according to the engineers at CI.

- 02.09.2024 | Application report

Creating complex components atom by atom

Voxel Innovations, United StatesPECM (Pulsed Electrochemical Machining) is a fast corrosion process that can form complicated geometries atom by atom. It is therefore ideal for the precise manufacturing of metal parts for high-tech applications. To integrate the core process into a fully automated, high-throughput production line, Voxel Innovations and Palmetto Mechatronics relied on the open PC-based control technology from Beckhoff.

Application videos

05.09.2024 | Multimedia

Precise control for multi-axis machines

Affolter Group SA, a Swiss company, relies on Beckhoff control technology to control complex machinery, e.g. for manufacturing clockwork for the timepiece industry. In this video, Vincent Affolter, Managing Director, explains which Beckhoff products are used.

11.12.2017 | Multimedia

Wassermann Technologies

The tool terminal developed by Wassermann Technologie in collaboration with system integrator Becker Engineering is characterized by an exceptionally compact design and high flexibility. This is largely due to the open and modular control technology from Beckhoff, with which machine tools can be seamlessly connected to the most diverse control systems available.