With the PC-based control technology from Beckhoff, highly dynamic axis movements and fast control functions of punching and nibbling machines can be realized for sheet metal working. Precisely programmable strokes, automatic tool change and the possibility to change the programming and setting of the machine during operation lead to a significant increase in productivity. In the field of punching, PC-based control technology can be used to achieve high product quality with a maximum product output. Due to the high performance of the Beckhoff IPCs and the EtherCAT communication system, stroke rates of more than 2000 strokes per minute can be realized. At these high speeds, high power is required in order to make adjustments to the mechanism in the micron range. In particular with high-speed presses, the dynamic effects resulting from the high centrifugal forces can be compensated.

Highly precise control optimizes punching and nibbling machines

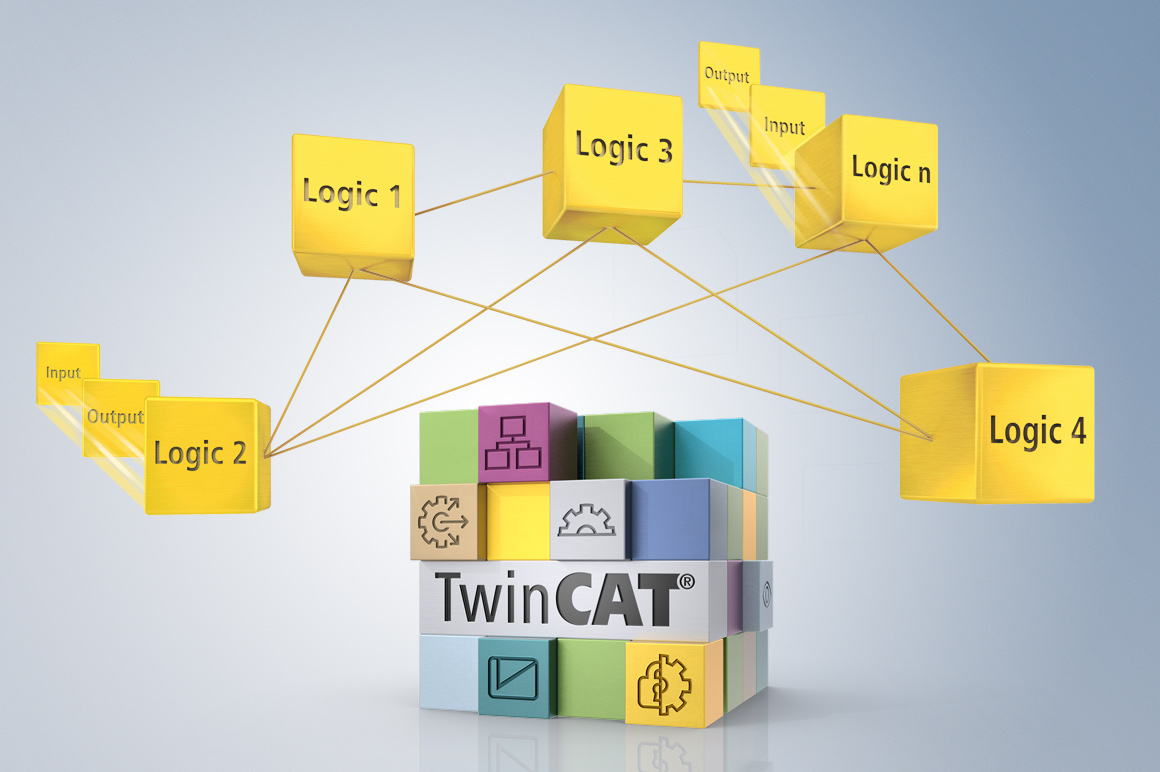

In the precision machining of sheet metal by punching or nibbling, several axes need to be synchronized with high repeatability. The motion control software TwinCAT NC and TwinCAT CNC take over the complete motion control of all servo axes. Machine manufacturers can incorporate their control technology know-how and design the sheet metal working processes individually. TwinCAT also guarantees subsequent changes and adaptations as well as the high flexibility required for nibbling. The controller automatically adjusts the processing parameters to the sheet thickness. Thanks to exactly programmable strokes special shapes can be punched very quickly.

In addition, the XFC technology supports superfast data transfer. The data from the press force monitoring or the tool fastening can be acquired with cycle times of less than 100 µs. However, this can only be achieved if several sensors can transmit their information to the high-performance control computer almost simultaneously. This replaces the installation of several decentralized devices, which would then have to be connected to one another in a complex manner. Another advantage of a central control unit is that complex envelope monitoring or other functions such as Vision and Machine Learning are much easier to integrate.

Application reports and brochures

- 20.03.2025 | Application report

Closed profile rings – the advantage of the fourth bending roller

Moser-Baer AG, SwitzerlandMoser-Baer AG in Switzerland is streamlining the production process for its world-famous railroad clocks with a new type of profile bending machine: With four bending rollers instead of the usual three, the Mobamatic MPB23 profile bending machine, with the mechanical platform developed and built by Moser-Baer, can bend a wide variety of profiles without straight end pieces. The automation specialist Pneutronic AG implemented the complete drive and control technology. PC-based control and the AX8000 multi-axis servo system with TwinSAFE ensure a compact design, precision, and safe operation without safety guards and laser scanners.

- 02.09.2024 | Application report

Scalable for the future with fully integrated, open control technology

Cincinnati Incorporated, United StatesCincinnati Incorporated (CI) has been building sheet metal processing equipment for 125 years and continues to support its durable machines for decades. The company is able to do this because it develops everything in-house, from the hardware to the software. However, the further development of proprietary control technology became too costly and challenging to support. Since the switch to PC-based control, the only limits to development have been physical, according to the engineers at CI.

- 06.11.2023 | Application report

High die casting quality through optimum control of vacuum generation

AJYa Vacuum Technology, ChinaIn die casting, vacuum generation in the shot chamber and mold cavity helps to avoid air and gas inclusions in the castings, as these would impair the stability of the finished parts. For this purpose, AJYa Vacuum Technology from China developed a complex but particularly effective multi-stage solution. A suitable control platform was implemented in cooperation with the automation partner Beckhoff.

- 11.10.2022 | Brochure

High performance built in: PC-based control for sheet metal working

As a specialist in PC-based control technology, Beckhoff provides proven, high-performance automation solutions for sheet metal working.

- 15.09.2021 | Application report

PC control guides precise shaping of the heaviest steel plates

Haeusler, SwitzerlandHaeusler AG, based in Duggingen, Switzerland, is a leading specialist in large-scale facilities for forming metal plates. At the end of 2020, a giant 1,245-ton straightening machine was delivered to one of the largest shipyards in China. The company explains that this plant, the largest of its kind in the world, is used in the production of oil tanker hulls. In this context, PC-based control technology from Beckhoff ensures that the enormous forces for precisely forming steel parts are guided in the right direction.